I will start with the thing that is on my mind most – and that is our inventory control system. Had the meeting with Op and Business Team – to find out why we haven’t been able to get up and running our inventory management system. It was supposed to be up and running 2 weeks ago, and yet not up. So, I asked everyone involved to share with me their view of why things are not working and why the project is not finished. In a way, it was a bit of a negative thing, as it encouraged finger pointing BUT I needed to see what the issue was that was blocking us.

What I saw was 6 very clever, smart and talented people – all with great ideas – but not supporting each other in achieving the goal. So, from here, it actually became apparent, that, at the end of the day, the issue was with me, since I haven’t offered solid direction nor plan in this area. But, I will get to this topic a bit later. Having said that, nevertheless, I heard a lot of excuses and good, solid reasons for why it wasn’t done. My answer – I don’t care – get it done.

So, in all honesty, I did not fully realize the scope of the ‘problem’ that was at hand till I started digging into the financial reporting. As I was digging, it became apparent that COG and inventory is a problem area. But what exactly? So, the great part about this meeting, was that I think at minimum I understood what was missing. Without getting into the nitty gritty here, bottom line, as of now have a good ‘stock’ tacking system, where we know how much stock is on hand, and what we are able to sell. BUT, what is missing, is the ability to see history of inventory, how much was used up, FIFO, etc.

Essentially, we know what we have on hand, we can nicely forecast what we need to buy, but we have no ability to know ‘control’ and ‘audit’ the inventory. This issue was quite apparent when my financial models where telling me that my cost of good for a given month should be X, but my ‘inventory’ people where showing me they consumed 2*X. There is no doubt about the consumption, since that is easy to report – but the discrepancy between X and 2*X – is the different between two digit profit margins and negative profit margins.

So, I know I have a problem, I know the area where it is, I know WHY its there, I understand the dynamic of HOW we got there – and (now comes the positive side) – and now I can fix it.

After getting clarity on the issue, I put this project responsibility on M…, and then removed ANY reasons for why she should not be able to get it done. Deadline is May 23rd.

Where where the opportunity comes, is that once we have an inventory control system in place, we will be able to look and see WHY we have this X vs 2*X discrepancy? So, although the problem is NOT solved, this is the first step in getting it solved.

So, following the guidelines steps in problem solving: 1. Learn, 2. Plan, 3. Act. Learning is done, Planning is done, now its Action. The good news is that, and I have seen this in the past, when a problem gains visibility, it can be solved and make huge impact on the company’s financial performance.

Long term, I’m am certain we will get this over with and we will get things much improved. Do I wish this was in place already? Yes. Does it frustrate the hell out of me, that it hasn’t been done for 3 years, and that JUST when its supposed to be done, its not done? Yes. BUT, do I see this as all bad? No, I feel frustrated with the pace BUT I also see how big a difference this will make – so although the present is not great – the future looks very good.

Getting into leadership – my personal life had encroached into the business very significantly this year – and where as in the first Q we would have set clear goals and objectives – I’m already in middle of Q2 – and still without a clear direction for everyone. That is not to say that we are not busy – we are – BUT – we are not focused – and that is on me. Could I, should I have done better here! Yes. So, when I feel frustrated with lack of progress, its actually frustration with myself that I haven’t been able to offer the company the kind of leadership and direction it needs. But again, to look on the positive side, we have done well, we have a lot of ‘balls in the in the air’ – and now its going to be my job, to decide which balls we are going to land, when, where and how fast. The fact that we have gone through this somewhat ‘traumatic’ period on our company – with one of the owners exiting – stood strong, managed to move forward – is a testament to the kind of team is in place. But, am I still frustrated that its not further along – YES! – can’t help it! IH2W8T.

In terms of leadership, there where two root causes for lack of it – first – 3 months of 2010 wasted on needless and wasteful personal stuff. No value, high cost. 2nd – the German project – and its uncertainty, had further slowed my planning down – since its such a large project – it added hesitation to planning – not knowing 100% in which direction to go. So, clarity on Germany will be had by May 15th – and it will then enable me to chart the course for the company for the remainder of the year. My focus now is to land all the balls that are up in the air, as quick as I can – to do my job – to lead, direct and offer strong direction. This inventory control project is just a symptom of a root cause that goes all the way to the top. As they say, the buck stops here – and it stops with me.

Had a fun meeting with S…, the interior decorator that did my apartment. We actually become friends over that project, but as with all of my friends over last few months, I haven’t really been in touch with him, so it was good to see him. He had done a lot of office space work, and given that we will very likely be looking for 1000 sq meter space in May – he can be a perfect guy. I’m looking at raw space, with some upfront investment, warehouse/office combo. In both, I need to make this space more customer friendly – not so much for ‘sales’ but to get it ready to onboard ‘Chinese’ suppliers – hence – we need to ‘pimp’ up this new space – so that the office helps us onboard suppliers. We discussed with S…, weather we need to make the space work for Chinese side only or international as well – I think international is the way to go, as I can see, that we may be outbound focused (China export) for now, but that pretty soon, we will be turning inwards (inbound into China) – and that will mean having ‘sales’ ready space for international standards. All this, in fact, is actually very cheap to do in China… but S… came up with some great ideas on how to setup some space, and actually make it so that it can get it for free, and also to gain flexibility of expansion without the need for future moves. Smart guy – experienced in this area. Yep, set it up so that its rent free! Not that rent is any big significant impact on bottom line, BUT, if its possible, then why not.

Talked with M…, and we confirmed our meeting in Germany and meeting location. That is all go. Meeting with Jeremy is also confirmed.

My goals for this week continue to be:

1. Finish the financial dashboard – my forecasting tool, my cash flow tool, my P&L and my reconciliation tool.

2. Major goal – get the ‘RedStores’ story ready – for this I need to do:

-

1. DCF projections

-

2. Cash burn

-

3. Establish how much I need to get 3 year runway

-

4. Determine the share structure, etc.

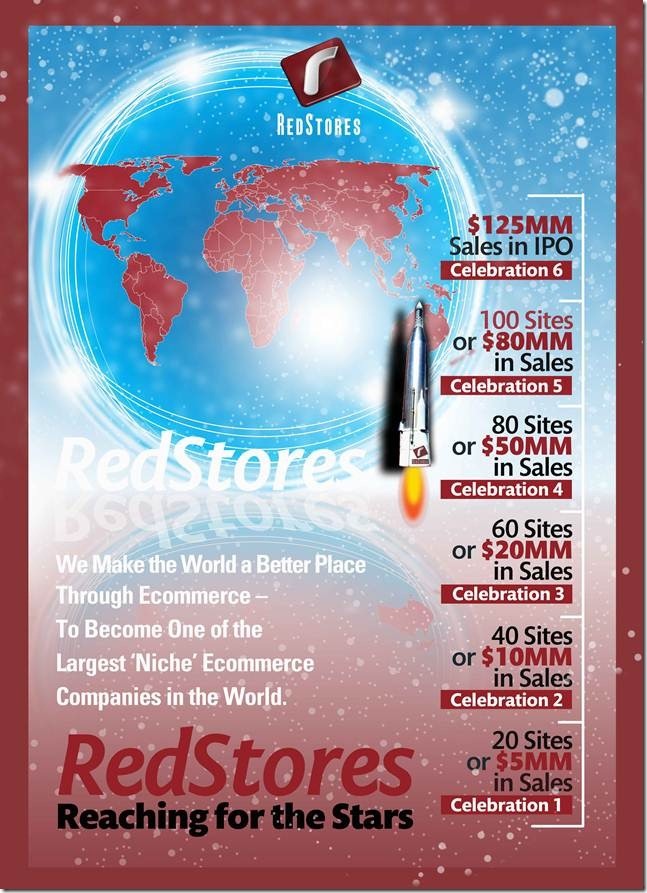

K…. came back with a cool design for the Celebrations for goal achievement.

So, overall, a bit drained today – had to really mentally push myself to look out onto the longer time frame – and look for the positives. They are there – and its good – but took a lot of ‘mental discipline’ to not indulge in the ‘problem’ but rather ‘in the solution’. Reading the blog, it probably doesn’t sound that I was all that successful it at – BUT – its much better than what I was thinking of writing before ‘refocusing’. Anyone want a CEO job? I’m just kidding of course – I love this – and that is why I care.

0 Comments